The semiconductor industry is continuously moving forward, which means that your devices have to constantly perform better. In turn, this places increasingly rigorous and stringent demands on the assembly processes.

KKM WORKS INC. helps by providing specific process-engineering support and expertise to qualify new devices, materials and processes, or improve existing ones.

Device Qualification

New devices need to run seamlessly in high volume production. For this to happen they need parameter optimization during qualification. But it can be challenging and time-consuming to define a qualification process. We can help by designing experiments and statistical analyses.

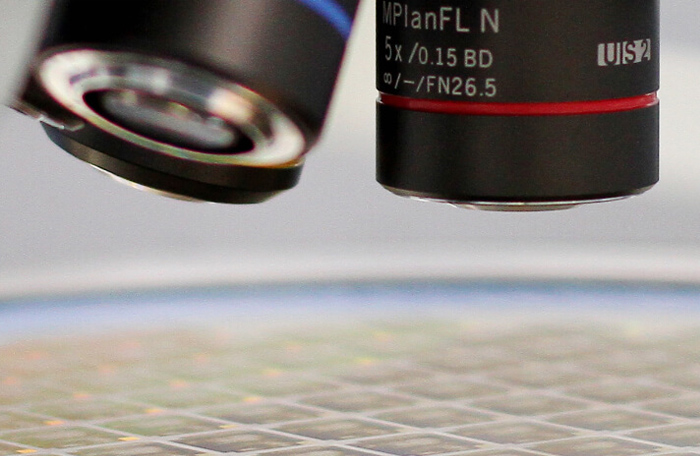

Process Qualification

The market demands ever-changing wafer fab designs, and process technologies need to keep up with them.

We can help you explore and qualify state of the art dicing processes, such as step cut dicing, laser ablation and DAF laser cutting to cater to different wafer materials.

And we can customize grinding procedures for thin wafer application.

We can help you explore and qualify state of the art dicing processes, such as step cut dicing, laser ablation and DAF laser cutting to cater to different wafer materials.

And we can customize grinding procedures for thin wafer application.